Mon. To Sat. 8:30-17:30

info@hanzo.cn

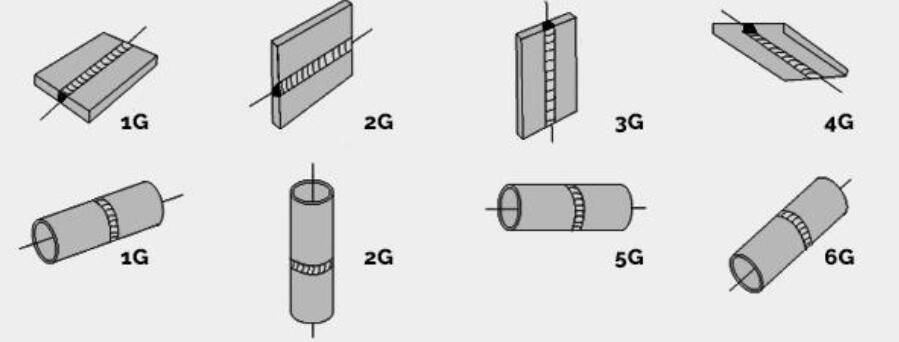

Each G level has specific technical requirements and application scenarios,

and welders need to undergo relevant training and certification to engage in these welding tasks.

1. **1G (Flat Position)**:

- The pipe is placed horizontally, and welding is performed on the outer surface of the pipe.

- Typically used for welding straight pipes.

2. **2G (Vertical Position)**:

- The pipe is placed vertically, and welding is performed on the outer surface of the pipe.

- Suitable for connecting vertical pipes.

3. **3G (Vertical Inside Welding)**:

- The pipe is placed vertically, and welding is performed on the inner surface of the pipe.

- Generally used for inner wall welding of vertical pipes.

4. **4G (Overhead Position)**:

- The pipe is positioned above the welder's head, and welding is performed on the upper side of the pipe.

- This welding position requires a higher level of skill.

5. **5G (Fixed Pipe Welding)**:

- The pipe is placed horizontally but cannot be rotated; welding is performed on the outer surface.

- Suitable for situations where welding must be done in a fixed position.

6. **6G (Inclined Position)**:

- The pipe is inclined at a 45-degree angle, and welding is performed in this position.

- This welding position has a high technical difficulty and requires the welder to have strong skills and experience.

|

|

|

+86-13923298312 info@hanzo.cn New Lighting Source Industry Zone B3, Luocun Town, Nanhai, Foshan, Guangdong, China.

|